|

Technical Parameters of main equipments for animal feed pellet production line

|

|||

|

No.

|

Product

|

Model

|

Power(KW)

|

|

1.Raw Materials Receiving And Crushing And Mixing system

|

|||

|

101

|

Screw Conveyor

|

TSLL16

|

2.2

|

|

102

|

Hammer Crusher

|

SFPZ56*30

|

18.5

|

|

103

|

Ribbon Mixer

|

LHY1.0

|

7.5

|

|

2.Pelleting System

|

|||

|

203

|

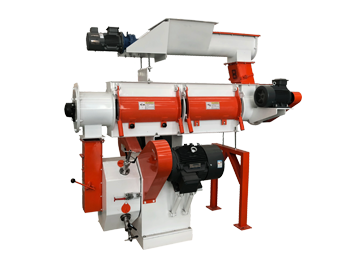

Pellet Machine(include control box)

|

SZLH250

|

24.95

|

|

3.Cooling System

|

|||

|

301

|

Belt conveyors

|

QBPS400

|

2.2

|

|

304

|

Counter Flow Cooler

|

SKLN11

|

0.75

|

|

307

|

Air Blower

|

4-72-4A

|

5.5

|

|

308

|

Screener

|

SFJZ60*1d

|

5.5

|

|

4.Packing System

|

|||

|

401

|

Belt conveyors

|

QBPS400

|

2.2

|

|

403

|

Packing Machine

|

|

2.2

|