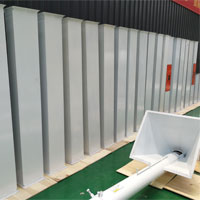

Reduced Investment: The small feed mill plant is designed to satisfy workshop conditions and reduced requirements due to its compact structure style.

Reduced Installing Cost: feed production line comes with simple installation instructions. After connecting the machine, you can go ahead to start using it immediately.

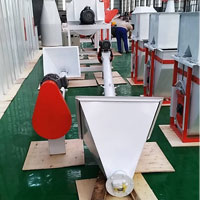

Minimized Manufacturing Cost: The animal feed plant can only be operated by one to two employers. Your profit will be increased due to low cost and less labor.

Comprehensive Application: The small feed mill plant is ideal for making feed pellets for a wide range of poultry animals and livestock.

Application

For making cattle, geese, pig, duck, chicken, sheep, rabbit, and other animals, livestock, and poultry feed.Such as 2-4mm diameter chick feed pellets and pig feed pellets.2-5mm rabbit feed pellets, 4-8mm cattle or sheep feed pellets. The last pellet length can be adjusted.

After installation and adjustment,we will train our customers work how to operate;

Training worker how to maintain and protect

According to features, we will make complete maintenance rules for you, containing how to maintain, when to maintain, and who maintains)

Our company after-sale department will call you at regular intervals, ask if maintain and give advice.