Raw materials: Ruminant feed mainly consists of grain-based raw materials such as corn, wheat, barley, and soybean meal (similar to animal feed), as well as coarse fiber-based raw materials such as grass, hay, and straw.

Feed production line mainly includes raw material receiving and cleaning system, crushing system, batching and mixing system, pelletizing system, finished product packaging system, and palletizing.

Crushing section: Due to the requirement of coarse crushing fineness for ruminant feed, this section adopts two crushers, each equipped with a crushing bin, which can simultaneously crush different raw materials and improve production efficiency. Before the raw materials enter the warehouse, impurities are removed by a magnetic separation device to ensure the safe operation of the crusher..

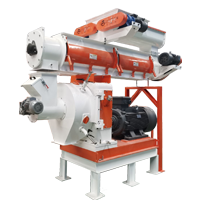

This animal feed mill machine is equipped with high-quality ring dies, pressing rollers, and advanced technology, which can meet the needs of different production capacities and specifications, and achieve ideal technical and economic benefits.

If you want to make different size pellets, the size, generally we mean the diameter of the pellets, you can buy several different size ring die.

The machine can make pellets for cows, cattle, sheep, and so on.

Application: for making cattle, sheep, rabbit, and other animals, livestock feed.Such as.2-5mm rabbit feed pellets, and 4-8mm cattle or sheep feed pellets. The last pellet length can be adjusted.

After installation and adjustment, we will train our customers to work how to operate;

Training worker how to maintain and protect

According to features, we will make complete maintenance rules for you, containing how to maintain, when to maintain, and who maintains)

Our company after-sale department will call you at regular intervals, ask if maintain and give advice.