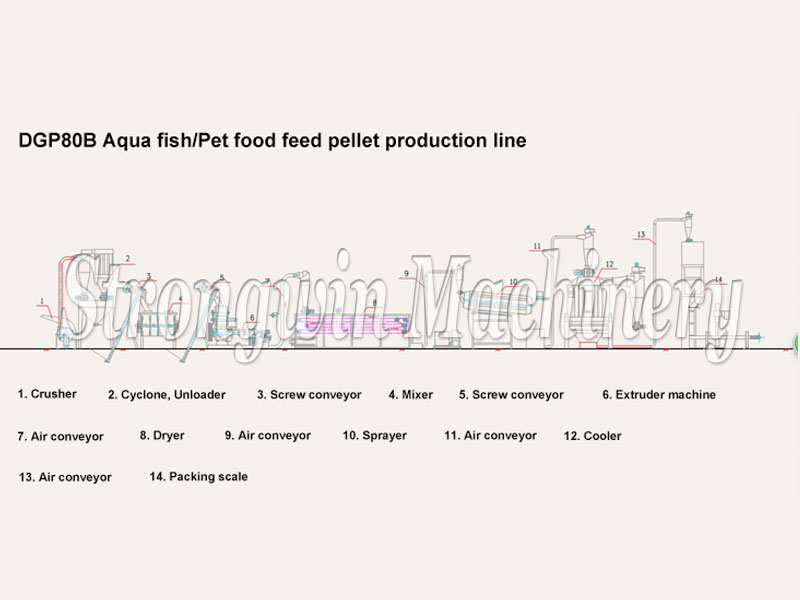

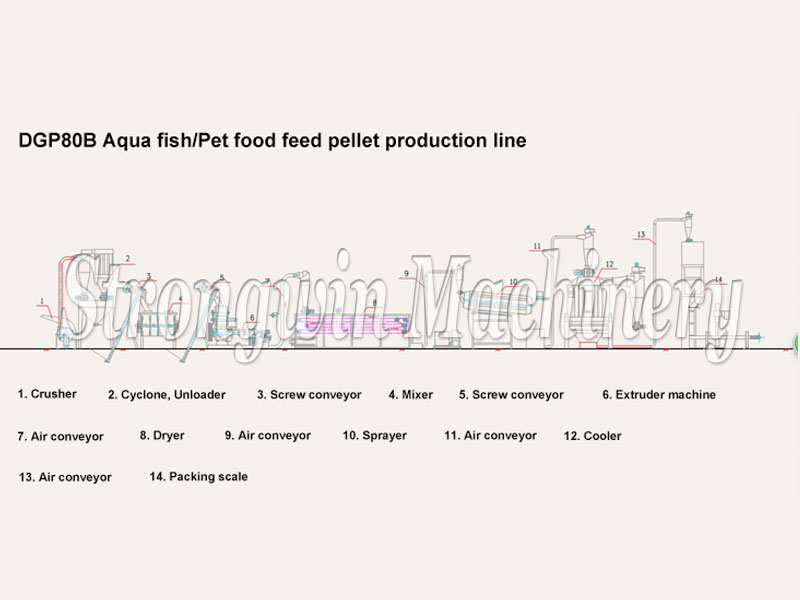

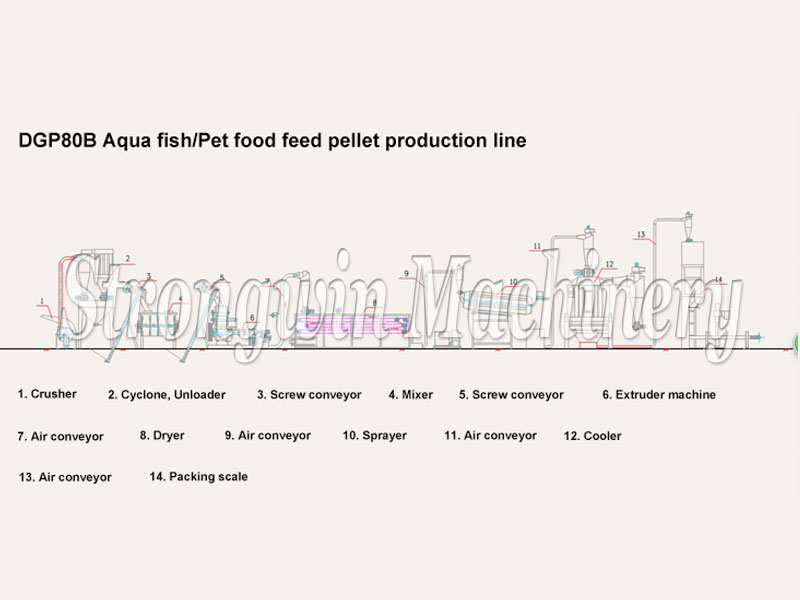

| Name | Capacity | Power | ||

| 1 | Crusher | 300-400kg/h | 11kw | |

| 2 | Dusting collection, bag dust collector and storage bin | Capacity of storage bin 0.5-1.0m³ | 0.75kw*2 | |

| 3 | Screw elevator | 300-400kg/h | 1.5kw | |

| 4 | Horizontal mixer | 100kg/batch,every batch is 10min. | 3kw | |

| 5 | Screw elevator | 300-400kg/h | 1.5kw | |

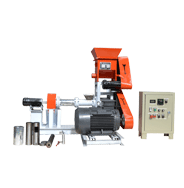

| 6 | Extruder DGP80-B |

200-300kg/h | Main Power: 22kw Cutting Power: 0.6kw Feeding Power: 0.8kw |

|

| 7 | Air conveyor | 200-400kg/h | Fan power: 2.2kw Discharge power: 0.75kw |

|

| 8 | Mesh belt dryer | 200-300kg/h | Heating power: 24kw Mesh Belt Power: 2.2kw Fan Power: 0.55kw |

|

| 9 | Air conveyor | 200-400kg/h | Fan power: 2.2kw Discharge power: 0.75kw |

|

| 10 | Spraying Machine | 300-500kg/h | Main Power: 0.75kw Oil Pump Power: 0.37kw |

|

| 11 | Air conveyor | 200-400kg/h | Fan power: 2.2kw Discharge power: 0.75kw |

|

| 12 | Counter current cooler | 100-150kg/batch,10- 15min | 3kw | |

| 13 | Air conveyor | 200-400kg/h | Fan power: 2.2kw Discharge power: 0.75kw |

|

| 14 | Packing scale | ≤300 bag/h. 1-25kg/bag |

0.75kw | |

| 15 | Power control system | |||

| Total Price | ||||