A wide range of raw materials such as corn, wheat bran, paddy, soybean meal, paddy rice, sorghum, etc. The raw materials are experienced by the high temperature and high pressure, which can kill salmonellosis and bacterial infections.

Besides floating fish feed and sinking fish feed, this production line can also produce high-quality feed for pets like dogs, cats, etc., applicable for fish farm holders and pet feed manufacturers.

The diameter of the pellets can be from 0.9mm-15mm.

We can also customize different fish feed pellet plants depending on your raw materials and specific requirements.

mainly sinking pellets, because the density of the pellets is big, if you want to make floating feed, so you need to buy one more extruder.

The fish feed pellet line is widely used in the production of animal feed, such as dogs, cats, fish, foxes, birds, and other pets.

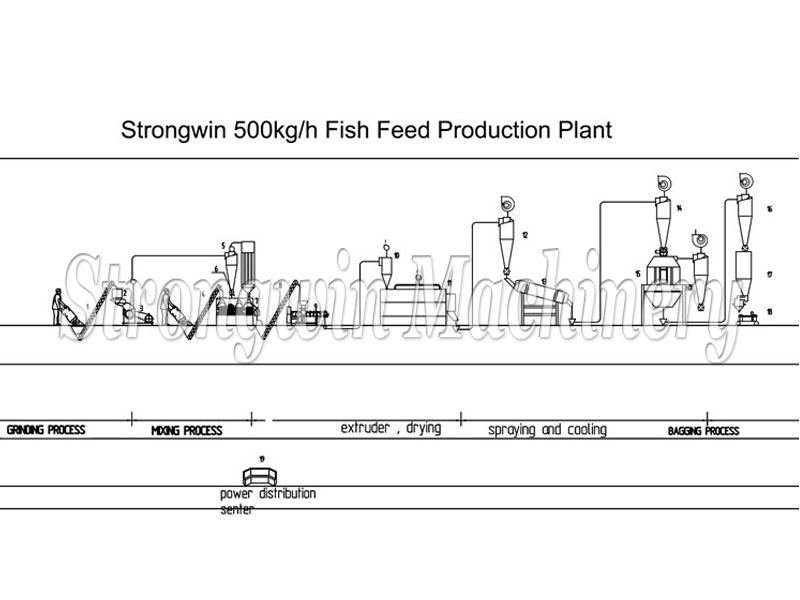

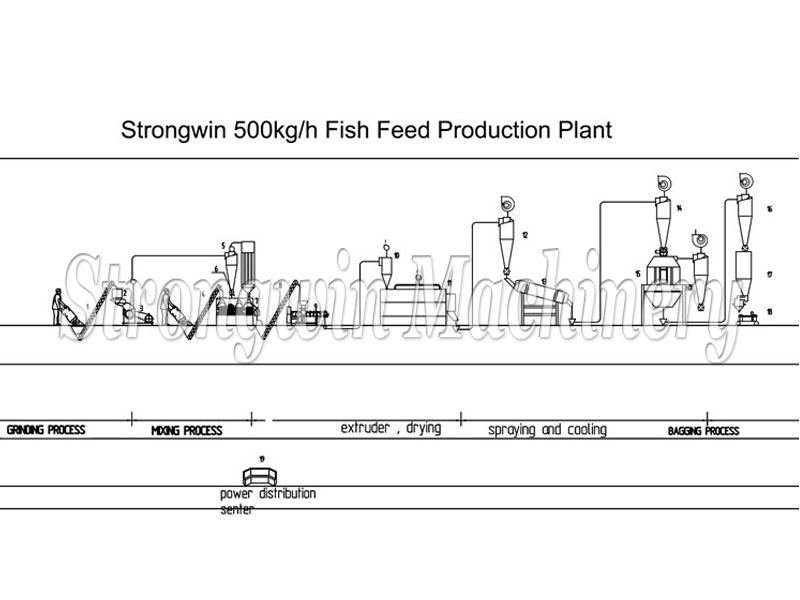

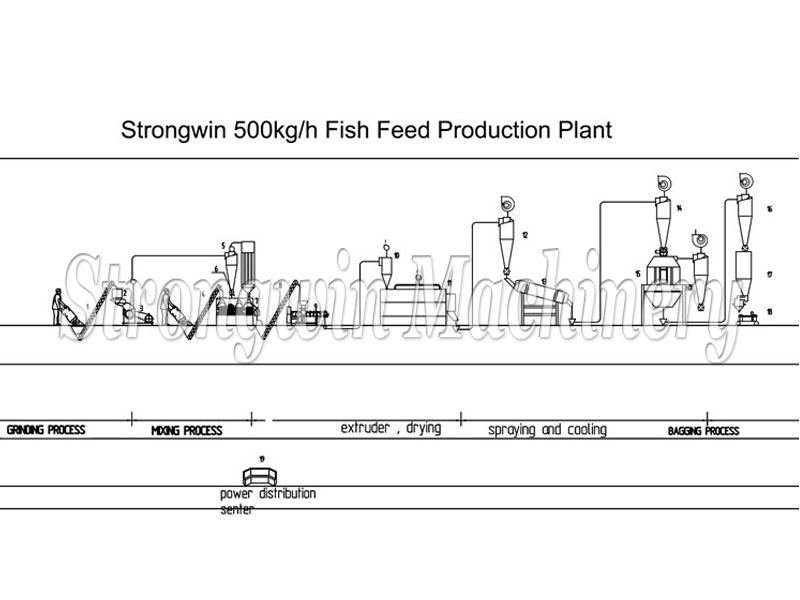

The fish feed pellet manufacturing process, from raw materials crushing to finished product packaging, can be finished at one time.

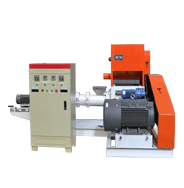

All the fish feed machines in this plant are with stable operation and advanced technology. It can satisfy the production demands of different customers in the current market.

The technological parameter, such as raw materials, temperature, and moisture, of this fish feed production plant is adjustable. Floating fish feed produced by this plant has a beautiful appearance, unique taste, and rice-nutrient, suitable for different fish and pets.