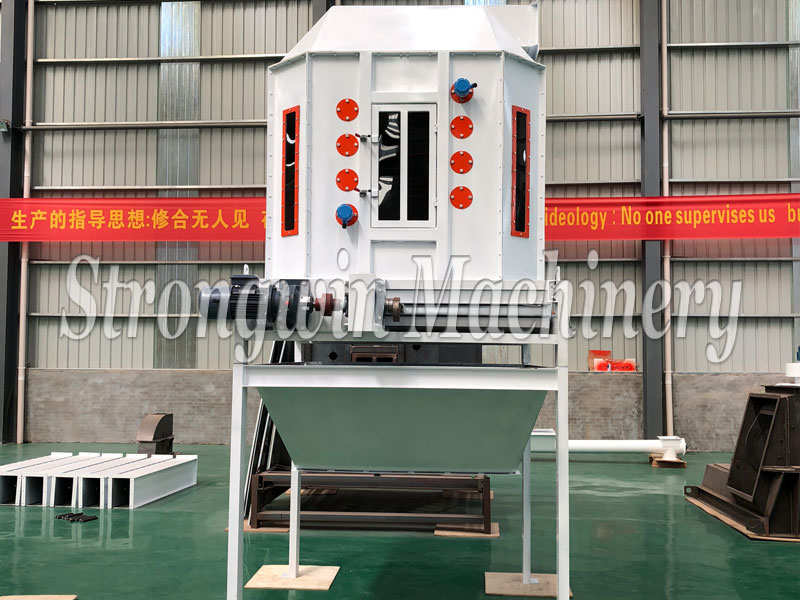

SKLN series counter flow feed cooler is suitable for cooling various kinds of pellets such as pelleted feed, expanded feeds, extruded feeds, and flake feeds, etc.

SKLN series counter flow feed cooler is structurally arranged vertically, the appearance is simple and beautiful;

On the principle of the advanced counter flow cooling, the SKLN series counter flow cooler is equipped with a reciprocating grate type discharging device, which is characterized by its smooth material flowing and uniform discharging;

The octagon cooling bin has eliminated the dead cooling corner, which is beneficial to the cooling treatment of materials;

The novel rotary spreader ensures materials for uniform and complete cooling with reduced breakage, featuring an adjustable range of material distribution and lowered power consumption;

There are some pressure-relief plates provided above the discharging device, which can greatly improve the working load of the discharging device, reduce SKLN series counterflow cooler’s distortion, and extend the service life of the parts

After cooling the finished product temperature is not higher than room temperature+3 ℃ ~ 5 ℃, suitable for the cooling of granular materials.

After installation and adjustment,we will train our customers work how to operate;

Training worker how to maintain and protect

According to features, we will make complete maintenance rules for you, containing how to maintain, when to maintain, and who maintains)

Our company after-sale department will call you at regular intervals, ask if maintain and give advice.

.jpg)